In Daly, California, the integration of Six Sigma methodologies has proven to be a key strategy for businesses to enhance operational efficiency and quality control. This approach, which includes six sigma certification levels such as Yellow, Green, and Black Belts, emphasizes reducing variability and defects in processes through a combination of statistical analysis and lean principles. The Six Sigma Black Belt holds advanced knowledge in using frameworks like DMAIC to address complex business challenges, leading to significant cost savings and improved operational excellence. Lean Six Sigma principles, drawing from Toyota's lean manufacturing and Motorola's statistical quality control, are particularly effective in streamlining operations and optimizing resource usage. By investing in Six Sigma training, organizations in Daly can expect to see notable improvements in productivity, quality, and profitability, positioning themselves as leaders of excellence within their community. This structured approach not only solves immediate problems but also fosters a culture of continuous improvement and root cause analysis, aligning with the overarching goal of achieving operational stability and customer satisfaction through discipline and data-driven insights.

Daly, CA, stands at the forefront of operational innovation, where businesses strive for excellence through the strategic application of Six Sigma methodologies. This article delves into the transformative power of Root Cause Analysis (RCA) as a critical component of Six Sigma, a data-driven approach to quality improvement that has revolutionized industries worldwide. By exploring the foundational aspects of Six Sigma certification and its practical application in California’s business landscape, we will uncover how local enterprises can harness lean Six Sigma principles to not only identify but also address process problems at their root. Join us as we navigate through the intricacies of Six Sigma’s impact, the pathways to becoming a Six Sigma Black Belt, and the mechanics behind this renowned methodology. A case study showcases how Daly, CA, businesses have successfully employed these techniques to achieve operational excellence, demonstrating the tangible benefits of Six Sigma training in real-world scenarios.

- Unlocking Operational Excellence with Lean Six Sigma in Daly, CA: An Overview of Six Sigma and Its Impact

- The Foundation of Six Sigma Certification: Pathways to Becoming a Six Sigma Black Belt in California

- Demystifying Six Sigma: What Is Six Sigma Methodology and How Does It Work?

- Leveraging Lean Six Sigma Principles for Process Improvement in Daly, CA Businesses

- The Role of Six Sigma Training in Identifying and Resolving Process Problems at Their Root

Unlocking Operational Excellence with Lean Six Sigma in Daly, CA: An Overview of Six Sigma and Its Impact

In Daly, CA, organizations are increasingly recognizing the transformative potential of Six Sigma as a means to achieve operational excellence. This methodology, which dates back to Motorola in the late 1980s, has since become a global standard for quality control and process improvement. Six Sigma certification signifies a formal acknowledgment of expertise in its principles, and it empowers professionals with the skills necessary to dissect complex business processes and enhance efficiency. The Six Sigma approach is rooted in a clear, data-driven pathway that leads to significant financial savings by reducing waste and errors. It encompasses a rigorous set of tools and techniques designed to optimize manufacturing and business processes. By implementing Six Sigma methodologies, organizations can identify and rectify defects, thereby streamlining operations and ensuring consistent quality in their products and services.

The lean aspect of Lean Six Sigma complements the Six Sigma framework by emphasizing the importance of value maximization through the elimination of waste. Lean Six Sigma principles guide businesses in Daly, CA to focus on what truly adds value, thereby accelerating performance improvements. A key role within this paradigm is held by the Six Sigma Black Belt, a professional who has mastered the Six Sigma training and methodology to lead improvement projects. These experts employ DMAIC (Define, Measure, Analyze, Improve, Control) as a roadmap for process improvement, ensuring that every step taken is measured against clear objectives to drive toward flawless performance. By adopting these comprehensive strategies, businesses in Daly can transform their operations to achieve not only quality and efficiency but also a competitive edge that is sustainable over the long term.

In the pursuit of operational excellence, Daly CA can significantly benefit from the application of Six Sigma methodologies. This data-driven approach to process improvement seeks to reduce variability in manufacturing and business processes through a set of principles and techniques. The Six Sigma certification framework, which includes belts such as the Black Belt, ensures that individuals are well-versed in its methodology, enabling them to effectively identify and address process problems at their root. Lean Six Sigma, an integration of Six Sigma’s statistical and quality control principles with the lean manufacturing philosophies, further streamlines processes by eliminating waste and optimizing resource usage. Through six sigma training, professionals at Daly CA can learn to employ problem-solving skills, data analysis, and project management tools to conduct root cause analysis. This enables the organization to not only enhance its product quality but also improve overall efficiency and profitability, thereby positioning itself competitively in the marketplace. By understanding the DMAIC (Define, Measure, Analyze, Improve, Control) framework, teams within Daly CA can systematically navigate each phase of the six sigma process, ensuring that every potential problem is scrutinized and addressed with precision and care. This systematic approach has proven to be a valuable asset for organizations looking to sustain long-term growth and success.

The Foundation of Six Sigma Certification: Pathways to Becoming a Six Sigma Black Belt in California

Six Sigma is a disciplined, data-driven approach and methodology for eliminating defects in manufacturing processes by systematically investigating the root causes of errors or defects in various industrial and business processes. At its core, Six Sigma aims to improve the quality of process outputs by defining, measuring, analyzing, improving, and controlling (DMAIC) the processes through rigorous and structured techniques. In California, as in any other region, the pursuit of Six Sigma certifications is a pathway to professional growth and expertise in operational excellence.

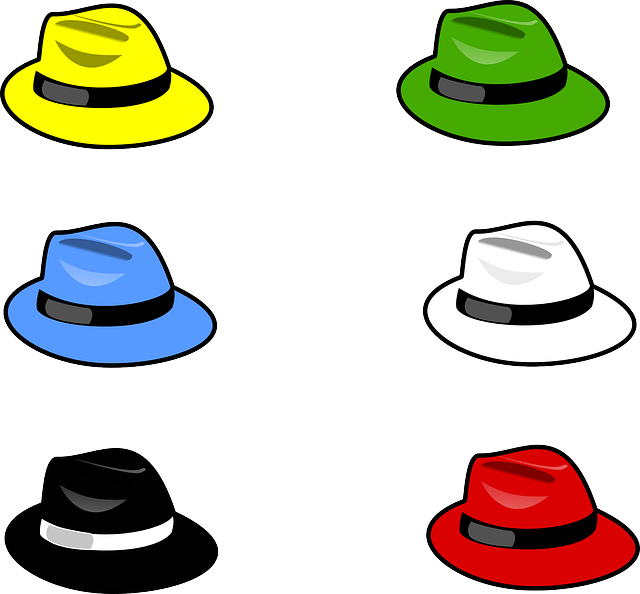

The journey to becoming a Six Sigma Black Belt in California begins with an understanding of what Six Sigma is at its foundation—a set of techniques and principles that seek to optimize processes for quality, efficiency, and predictability. The lean Six Sigma certification pathway combines the principles of lean manufacturing with the Six Sigma methodology, offering a comprehensive approach to process improvement. Aspiring professionals start with Yellow Belt training, which familiarizes them with the basics of the Six Sigma philosophy and its tools. Building upon this foundation, Green Belt training deepens their understanding and equips them with hands-on experience in leading small process improvement projects. The zenith of this certification hierarchy is the Black Belt level, where individuals are fully trained to lead complex projects and problem-solving teams. Six Sigma Black Belts are proficient in advanced statistical methods, master project management, and apply their knowledge to drive significant improvements in organizational performance, making them invaluable assets within any California-based organization seeking to excel through operational excellence.

Demystifying Six Sigma: What Is Six Sigma Methodology and How Does It Work?

Six Sigma is a disciplined, data-driven approach and methodology for eliminating defects in manufacturing processes by systematically seeking out and removing the causes of defects and variability as part of a sequence of increasingly wider tiers of prevention. At its core, Six Sigma aims to improve the quality of process outputs by identifying and removing the causes of defects (errors) and minimizing variability in manufacturing and business processes. The Six Sigma methodology encompasses a set of principles and tools, including Lean Six Sigma, which combines the principles of Six Sigma with those of Lean manufacturing to achieve more efficient and effective processes.

The Six Sigma certification process is structured around different belt levels—Yellow Belt, Green Belt, and Black Belt—each representing a deeper level of commitment and expertise. A Six Sigma Black Belt, for instance, is a master of the Six Sigma methodology who leads projects to achieve breakthrough process improvements. The Six Sigma training for these belts involves learning how to use statistical tools like design of experiments (DOE), hypothesis testing, and process mapping to solve complex problems. The Lean Six Sigma principles focus on value, value streams, and flow, as well as pulling andon as needed; aiming to deliver a exceptional patient experience without overburdening the system with unnecessary work. This systematic approach to problem-solving allows organizations to consistently produce products and services that meet customer expectations while minimizing waste and optimizing resources.

Leveraging Lean Six Sigma Principles for Process Improvement in Daly, CA Businesses

In Daly, CA, businesses are increasingly turning to Lean Six Sigma principles as a potent methodology for process improvement, aiming to enhance efficiency and reduce variability in their operations. Lean Six Sigma, which combines the lean manufacturing practices of Toyota’s production system with the statistical quality control of Motorola’s Six Sigma, offers a comprehensive approach to optimizing processes. By achieving this synergy, local businesses can identify and eliminate defects, cut waste, and improve overall customer satisfaction. Six Sigma certification, indicative of a professional’s mastery of these techniques, is particularly valuable for organizations looking to implement the Six Sigma methodology at scale. A Six Sigma Black Belt, for instance, possesses in-depth knowledge and expertise in applying Six Sigma tools and methodologies—such as DMAIC (Define, Measure, Analyze, Improve, Control)—to complex business issues. This level of training ensures that businesses in Daly can navigate the nuances of process improvement with a systematic approach, leading to significant cost savings and operational excellence. Companies that invest in Six Sigma training for their staff enable these professionals to effectively manage projects, analyze data, and solve problems, ultimately driving continuous improvement across all levels of the organization. By leveraging these principles, Daly businesses can expect not only to streamline their operations but also to enhance productivity, quality, and profitability, setting a new standard for excellence within the community.

The Role of Six Sigma Training in Identifying and Resolving Process Problems at Their Root

In the realm of process improvement and problem-solving, Six Sigma stands out as a potent methodology for identifying and resolving issues at their root cause. This disciplined, data-driven approach to quality control and process management, known as Lean Six Sigma, integrates lean principles with Six Sigma’s robust statistical analysis to enhance operational efficiency and effectiveness. Six Sigma certification, particularly the esteemed Six Sigma Black Belt designation, equips professionals with the knowledge and skills necessary to implement the Six Sigma methodology effectively. These certified experts delve into process operations to pinpoint anomalies and inefficiencies, applying Lean Six Sigma principles such as DMAIC (Define, Measure, Analyze, Improve, Control) to systematically dissect problems. The training involved in achieving Six Sigma certification encompasses a comprehensive understanding of statistical tools, project management techniques, and problem-solving methodologies that enable professionals to not only recognize process deviations but also to address the underlying causes systematically. By leveraging this structured approach, organizations can achieve a significant reduction in variability and defects, leading to improved product quality, operational stability, and ultimately, customer satisfaction. The Six Sigma training thereby acts as a catalyst for continuous improvement, fostering an environment where root cause analysis is not just a task but a culture within Daly CA’s business operations.